Project Background

Farrleey Environmental Protection has created a "dust-free workshop" for a leading domestic battery enterprise.

The core processes of lithium battery manufacturing, such as batching, mixing, die-cutting, winding, and welding, generate dust with significantly different characteristics, including ultra-fine particle size material dust, thin and light metal scraps, and flammable and explosive metal fumes. Due to the diverse nature of the dust, a single dust removal solution is difficult to handle all types effectively, leading to dust accumulation in the workshop. This not only poses a serious threat to the health of workers and production safety but also may directly cause quality defects such as internal micro-short circuits and self-discharge in batteries, significantly reducing product consistency and reliability.

Solution

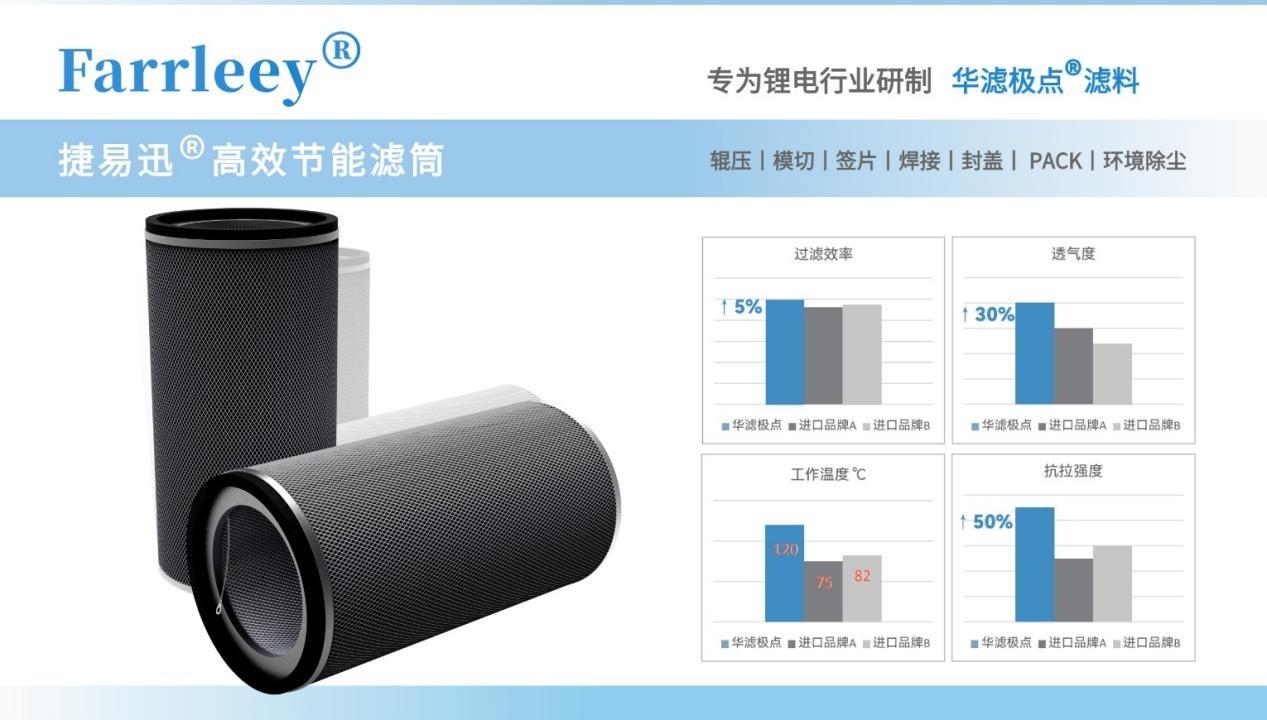

Farrleey Environmental Protection has introduced the

"section-customized" GEELSON® folded filter cartridge solution to

achieve staged precise filtration:

Batching section:

The GEELSON® folded filter cartridge with extreme filtration

technology is selected to efficiently capture sub-micron dust, ensuring the

cleanliness meets the standards of lithium-ion battery workshops.

Die-cutting section:

The GEELSON® folded filter cartridge with extreme point

technology is chosen. The filter material surface undergoes special treatment,

with a wear resistance of over 15,000 times and a dust removal stripping rate

of over 88%, effectively reducing the risk of fire from the source.

Welding section:

The high-precision Farrtex type GEELSON® folded filter

cartridge is configured, with a filtration efficiency of over 99.9%, and it can

completely eliminate the risk of explosion caused by dust accumulation.

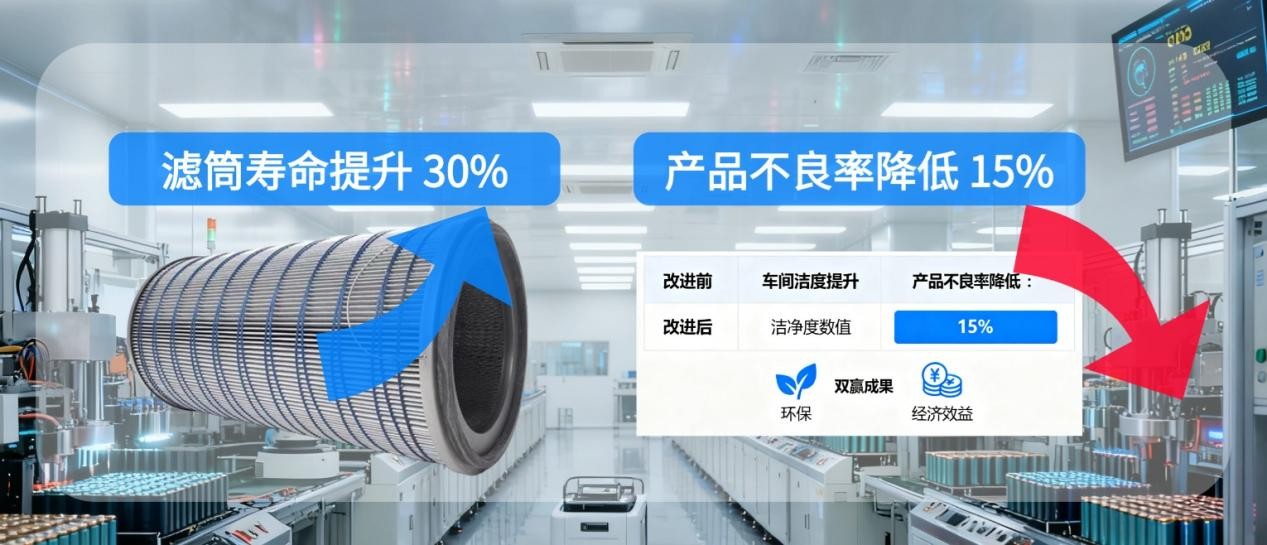

Advantages of GEELSON filter cartridge lifespan

In the harsh production environment of lithium-ion batteries, the

lifespan of the filter cartridge directly affects operating costs and

production stability. The GEELSON® folded filter cartridge uses

high-quality filter materials and precise structural design, with a lifespan

over 30% longer than conventional products under the same working conditions.

Its surface filtration and ultra-fine fiber structure can effectively delay

dust penetration, reduce the frequency of dust removal and mechanical wear,

ensuring long-term efficient and stable operation, and significantly saving

maintenance costs.

Application results

After the deployment of this solution on a leading domestic battery production line, the emission concentration of each section has been stably up to standard, the workshop cleanliness has been significantly improved, reaching the industry-leading level, effectively ensuring the consistency and safety performance of battery products, helping the customer reduce product defect rate by 15%, achieving a win-win situation in environmental protection and economic benefits.

Choosing Farrleey Environmental Protection's customized solution is like equipping each critical process with a professional dust protection expert.

Farrleey Environmental Protection hotline: 4008366909

Scan the code to learn more