GEEWING® series dust filter bags are the basic products of Farrleey. With more than 20 years of experience in the application of bag filters, our company has a large amount of data support for various working conditions, providing the foundation to develop different types of filtration products that meet different working conditions. Farrleey's GEEWING® series PTFE felt with PTFE membrane bags are widely applied in waste incineration, industrial hazardous waste disposal, medical waste disposal and other fields.

After 30 years of development and exploration of waste incineration, the entire technological process, including the major unit equipment and local systems, has reached the foremost level. Among them, the flue gas system process is as follows:

Waste power generation: In 2017, 70% of the 359 operating waste incineration plants did not disclose monitoring data, especially dust particles (the above data)

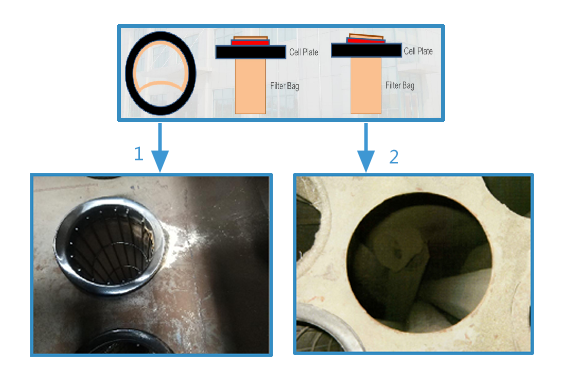

Analysis of the current status of filter bags: PTFE membrane filter bags have become a must for waste incineration and hazardous waste disposal industry for ultra-low emission of dust particles, but there are still a series of problems

Semi-dry method:

Ga (OH) 2 solution

Dry method:

hydrated lime powder

Bag dust

Activated carbon

SNCR

Selective

non-catalytic

reduction

Pre-sale

Pre-sale

On sale

On sale

After sales

After sales

Pre-sale

Pre-sale

On sale

On sale

After sale

After sale

Scan the code to learn more